Loading of empty spools

STEP ONE:

STEP TWO:

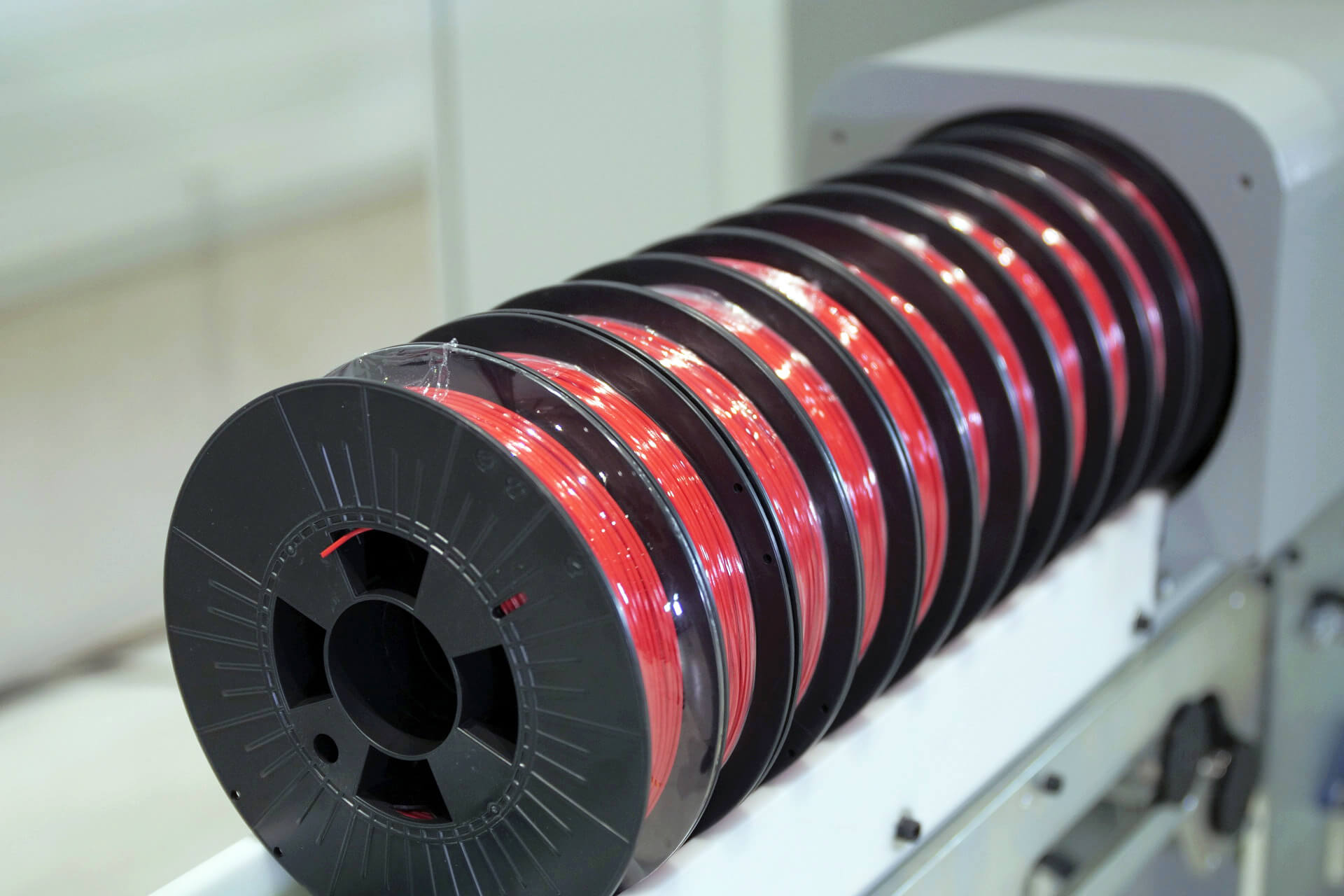

Filament winding process

STEP THREE:

Unloading of full spools

The 3D printing

industry is experiencing significant growth and as printing technologies continue to evolve, the demand for such products is rising rapidly.

Filament manufacturers will need to increase speed and efficiency to meet the demands and growing competition.

FilaPack by Windak Group offers its customers winding and packaging equipment for the manufacturing of filament products, such as PLA and other common filament materials. The equipment is either for direct inline packaging in tandem with the extrusion line or as offline packaging in a rewind line application.

FilaPack by Windak Group offers two systems

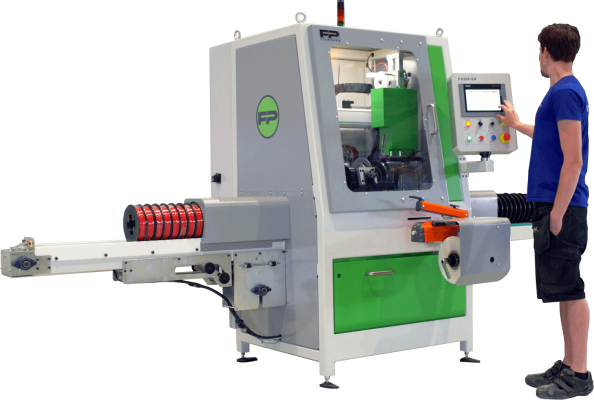

• Fully automatic for autonomous running during many hours of production directly onto 200 mm spools. Machine model FilaSpooler FS200-SA.

• Semiautomatic winding primarily used for bulk reel winding on spools up to 400 mm diameter. Machine model FilaSpooler FS400-DM.

ADVANTAGES

The machines are designed for automatic packaging of the filament spool directly in line with the extruder or off-line with a Pay-off. The fully automated FilaSpooler, removes the costly off-line rewind operation, and one operator can cover many more extrusion lines than with a manual spooler/winder at the end of the extrusion line.

This leads to:

- higher output per production hours

- higher line speed

- lowered operational cost

FilaPack by Windak Group series of spoolers ensures the perfect outlook of the filament spool, giving your end customers a high-quality package that smoothly unwinds the filament material.

Automated production processes and high-quality packaging directly translate to a bigger bottom line.

FEATURES of FilaPack FS200-SA

Runs in conjuction

with an accumulator allowing for spool changes and precision tension control.